Introduction

In the coming years 70% of the population will live in cities. Skyscrapers are a solution to densify cities in order to save urban soil and public budgets for city services, but in this scenario only a small percentage of the urban population will have access to a healthy eating. At present, throughout the world, over 80% of the land that is suitable for raising crops is in use. Urban agriculture arises as a solution that provides with healthy food without compromising the environment. But how to achieve this when cities have to deal also with polluted air and water resources? how to get a sustainable life inside a 21 century skyscraper community? How can we do to transfer the knowledge of producing fresh natural food to the next generations?

Producing indoor organic hydroponic vegetables

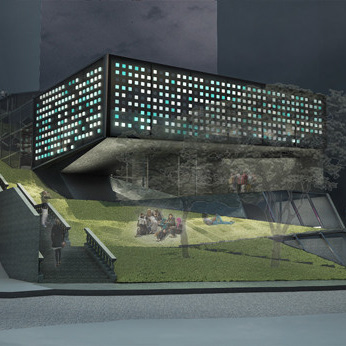

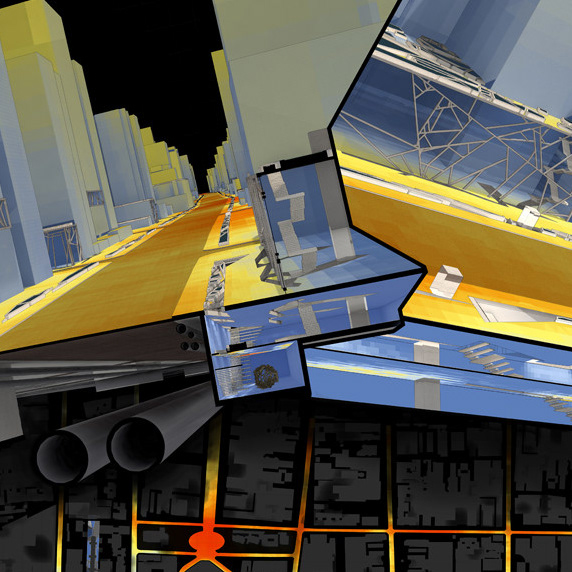

Skyfarm is one possible answer to achieve these goals by allowing people to grow healthy and organic food inside a vertical city, and also being a sustainable and useful infrastructure that will also be a public space.

SkyFarm will use the latest technology on urban farming solutions, it will be a sustainable vertical hydroponic farming facility, not only economically and ecologically but also socially. We want to create a new kind of indoor public space, a topographic landscape, that seeks to achieve a sense of belonging on its users and that is able to build a local identity for the community.

Skyfarm will not only provide people with healthy food and be the building public plaza but will also be an education facility that will show up the production process, to transfer the knowledge in order to raise awareness and replicate in other interior building spaces.

Design process

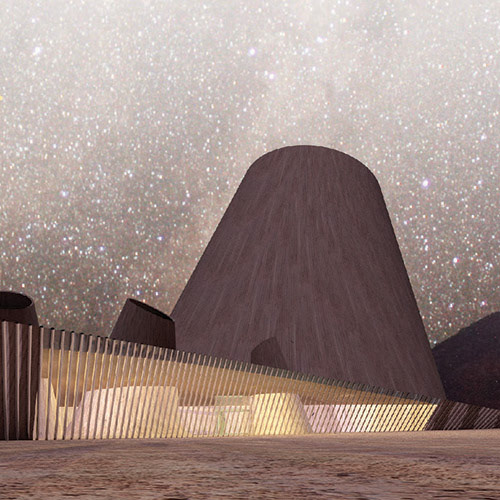

The creative concept of the project originates from design guidelines and program inputs, following a logical development, from analyzing the situation context to its possible materialities and assembly. Process, form and structure follow these premises, resulting on a design that reacts to its particular situation and program requirements. The main challenge was to combine the best plaza usability with a maximum possible farm facility area.

To achieve this, we propose a public indoor landscape, an ethereal topography that host inside it the farm facility. This topography is the result of the two main program requirements: first, the need of a restricted access and a hygrothermic controlled area, and second, an open and welcoming public space. As a result, the atrium floor rises in the areas where the farm needs room, and it descends in areas where a path connection is needed. This translucent topography will show up how vegetables are produced, and also will connect all the levels in a public path, generating social areas and meeting points.

Design guidelines

To build an indoor topographic landscape, to enrich the building users experience.

To keep the atrium usability as a connector and a meeting place.

To connect all the atriums levels in a public path.

Due to its particular location, it should be a prefabricated easy mounting structure, plus lightweight and low maintenance.

A unique big fluid space, where all the social activities could be easily detectable and usable.

To provide for the indoor farm facility the maximum possible production area.

To keep the atrium usability as a connector and a meeting place.

To connect all the atriums levels in a public path.

Due to its particular location, it should be a prefabricated easy mounting structure, plus lightweight and low maintenance.

A unique big fluid space, where all the social activities could be easily detectable and usable.

To provide for the indoor farm facility the maximum possible production area.

Construction process / Structure follows form

The creative concept of the project originates from design guidelines and program inputs, following a logical development, from analyzing the situation context to its possible materialities and assembly. Process, form and structure follow these premises, resulting on a design that reacts to its particular situation and program requirements. The main challenge was to combine the best plaza usability with a maximum possible farm facility area.

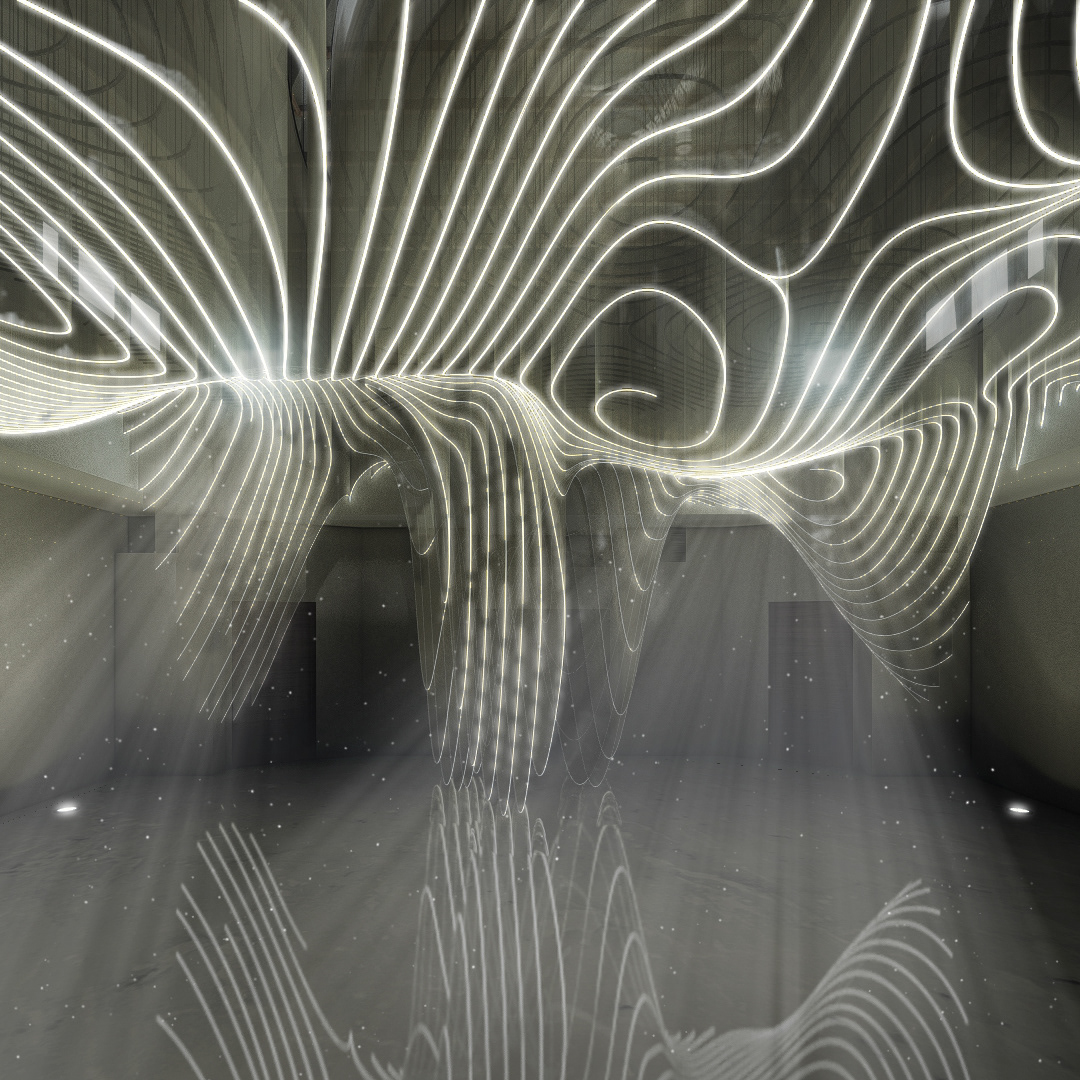

Skyfarm will be made mainly from galvanized steel pipes and joints, galvanized steel hollow sections and polycarbonate sheets. Its components will be produced outside the building and mounted together on situ. There will be 5 types of polycarbonate sheets, from totally clear to opaque sheets, according to a previous defined pattern.

Assembly

The galvanized steel pipe components for the main structure will be assembled together using customized metal joints. The topographical surfaces and stairs will be made from polycarbonate sheets.

The metal joints were first created by a parametric software and then casted from a mold made from a 3D printer. The polycarbonate surfaces were triangulated using also a parametric software and the resulting pieces will be then specifically made with a laser cutting and mounted together with galvanized steel frames and beams.

Technology

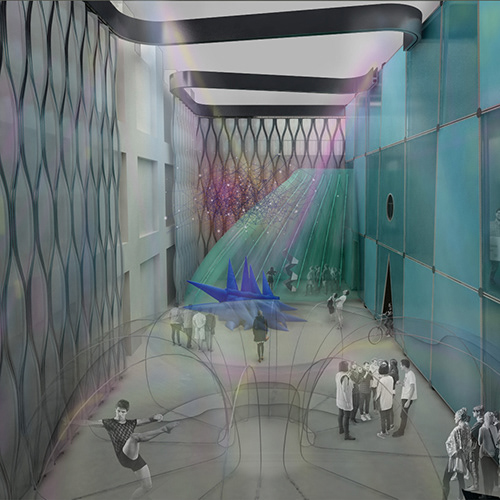

Hydroponics is an agriculture technology for growing plants in nutrient solutions (water containing natural fertilizers) with or without the use of an artificial medium to provide mechanical support. Indoor hydroponics farms allow also to grow vegetables in a controlled environment without the use of agro toxics and air pollution.

Skyfarm project will be based on the ZipFarm technologies, adapted to the special needs that requires this location. This is a proved and technology based on vertical hydroponic racks systems, and a system of led lights and irrigation.

Advantages of Skyfarm hydroponics system

The Hydroponic indoor farms use less water and space than conventional farms, and grows food more efficiently, as much as 350 times more crops per square foot than a typical farm. The advantages of indoor vertical farms compared to traditional farms are:

1 - Rational and less use of water by reusing it up to 90%.To keep the atrium usability as a connector and a meeting place.

2 - More efficiently production in the same planting area.

3 - Fastest growth, up to 2 times fastest.

4 - Not need to use herbicides or agro toxics.

5 - Not depend on weather conditions nor natural seasons, nights or days.

6 - Light, air humidity and temperature are all tightly controlled.

7 - Low carbon footprint by bypassing extensive transportation of the produce, grow locally to sell locally.

8 - Possibility of data collecting by using sensors, to analise and improve the production.

2 - More efficiently production in the same planting area.

3 - Fastest growth, up to 2 times fastest.

4 - Not need to use herbicides or agro toxics.

5 - Not depend on weather conditions nor natural seasons, nights or days.

6 - Light, air humidity and temperature are all tightly controlled.

7 - Low carbon footprint by bypassing extensive transportation of the produce, grow locally to sell locally.

8 - Possibility of data collecting by using sensors, to analise and improve the production.

_

CREDITS

Location: Changsha, Hunan, Brazil

Organization: SkyCity and Broad Town

Year: 2017

Status: Winner Project for the Competition

Program:

Indoor Farm: 320m2

Team: Jeff Chicarelli and Matías Gatti

Organization: SkyCity and Broad Town

Year: 2017

Status: Winner Project for the Competition

Program:

Indoor Farm: 320m2

Team: Jeff Chicarelli and Matías Gatti